GRP Gratings

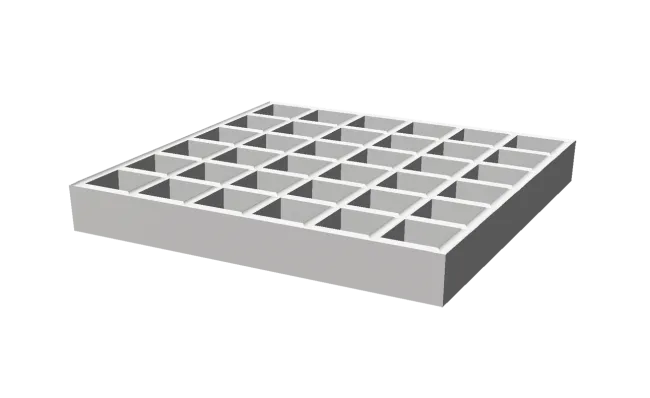

We supply composite gratings in all shapes and sizes. Our glass fiber reinforced plastic (GRP) gratings are made by combining fiberglass and thermal resin in a mold. This creates a plastic grid with mesh openings. The GRP gratings are available in different sizes, meshes, colours, thicknesses and finishes. Whatever you choose, our gratings meet the European standard as standard.

Our standard mesh gratings are fiberglass reinforced plastic gratings with meshes of 38×38 mm. These gratings are suitable for various applications. For example, they are often used in aggressive environments, such as salty or acidic environments. You can think of applications in the agricultural sector, within offshore projects, in the chemical industry and in cooling towers.

Many advantages

Our plastic gratings are fibreglass reinforced, have an expected lifespan of more than 50 years, are wear-resistant and have a concave non-slip surface on one of the two sides as standard. This surface has no negative influence on the load-bearing capacity of the gratings. In addition to this standard finish, you can choose a flat or non-slip finish. The gratings are particularly suitable for industrial purposes. Our glass fiber reinforced plastic gratings are functional and make the conditions for personnel safer when working within these industries.

Our standard mesh gratings are fiberglass reinforced plastic gratings with meshes of 38×38 mm. These gratings are suitable for various applications. For example, they are often used in aggressive environments, such as salty or acidic environments. You can think of applications in the agricultural sector, within offshore projects, in the chemical industry and in cooling towers.

Many advantages

Our plastic gratings are fibreglass reinforced, have an expected lifespan of more than 50 years, are wear-resistant and have a concave non-slip surface on one of the two sides as standard. This surface has no negative influence on the load-bearing capacity of the gratings. In addition to this standard finish, you can choose a flat or non-slip finish. The gratings are particularly suitable for industrial purposes. Our glass fiber reinforced plastic gratings are functional and make the conditions for personnel safer when working within these industries.

Custom Made

Custom gratings

Have you not yet found the composite grating you want?

No problem: Danytex is a specialist in customization. We are happy to develop a schedule that fully meets your wishes.

Smart design, efficient installation

When installing GRP gratings, everything revolves around a well-considered installation plan. Yet we often see that this is not sufficiently taken into account in the design phase. The result? Unnecessary sawing, extra costs and waste of materials. At Daléro, we believe in an efficient approach. Our specialists like to think along with you at an early stage, so that we can arrive at the best solution together. By providing smart advice on the right sizes and types of gratings, we ensure a fast and cost-efficient installation.

The advantages of composite gratings

No corrosion

Composite will not rust or rot and can withstand all weather conditions

Sustainable

Has a lower CO2 consumption than wood, steel and concrete and has an expected lifespan of 50+ years

Low maintenance

Composite is easy to assemble and requires little to no maintenance

Strong

In some cases, composite is even stronger than steel

Fire resistant

The use of specific resins makes composite fire-resistant

Custom design

Composite can be designed and produced in many possible shapes

Chemical resistant

Composite resists highly aggressive chemicals

light weight

Composite profiles are considerably lighter than steel profiles